As the manufacturing landscape continues to evolve, 3D print technology stands out as a transformative force driving significant efficiency gains across various industries. According to a report by Wohlers Associates, the additive manufacturing industry is projected to grow to over $35 billion by 2024, highlighting the increasing adoption of 3D printing in production processes. This technology not only shrinks lead times and reduces waste, but it also enables manufacturers to create complex designs that were previously impossible or cost-prohibitive. Furthermore, a study by Deloitte indicates that early adopters of 3D printing report reductions in product development costs by up to 75%, showcasing its potential to revolutionize traditional manufacturing paradigms. As businesses seek to enhance operational efficiency and remain competitive, understanding the compelling reasons behind the shift to 3D print technology is more crucial than ever.

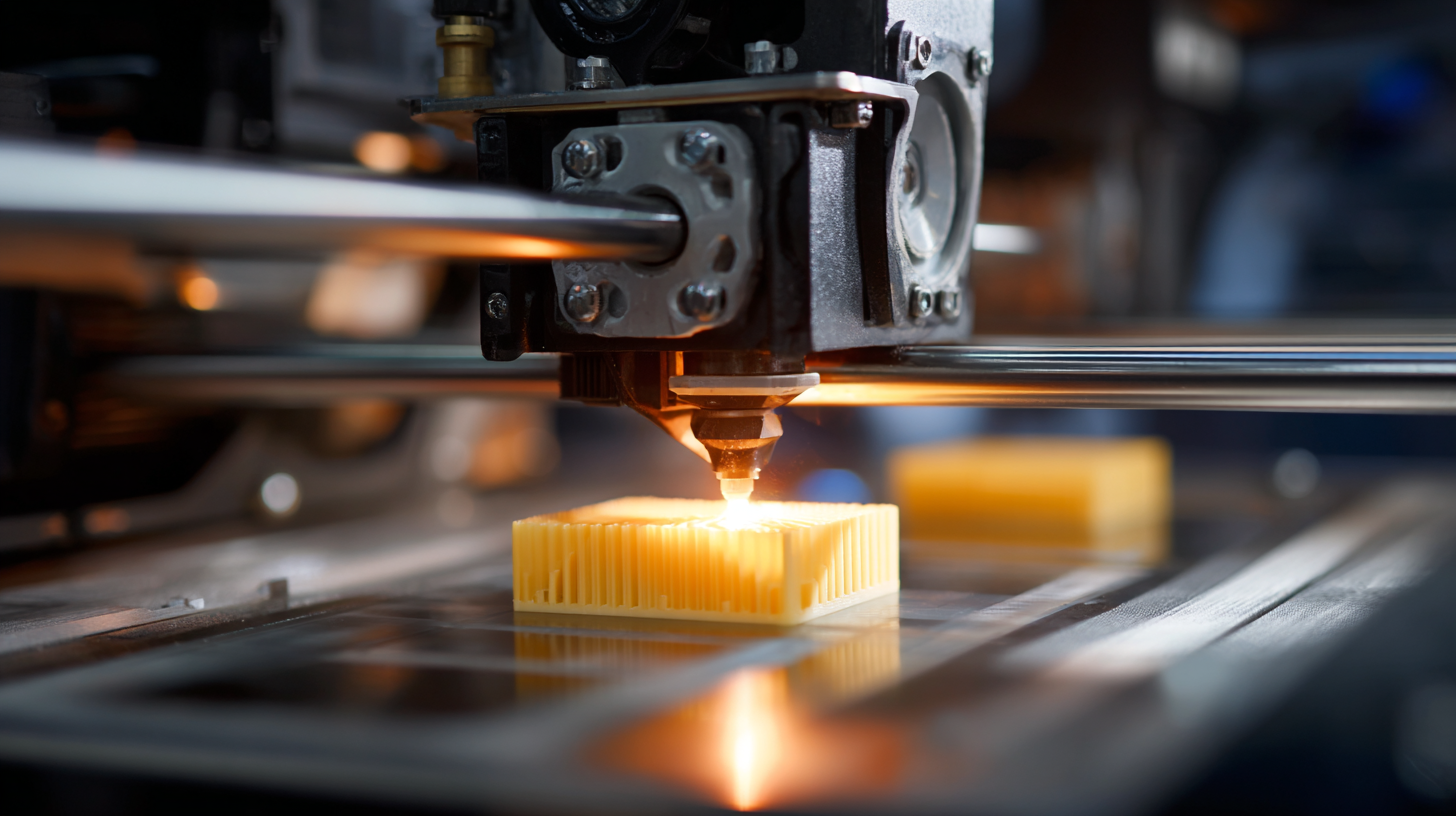

The adoption of 3D printing technology is revolutionizing manufacturing workflows by introducing unprecedented efficiencies and flexibility. Unlike traditional manufacturing methods that often involve multiple steps and the need for complex machinery, 3D printing allows for rapid prototyping and production straight from digital models. This streamlined process reduces lead times significantly, enabling manufacturers to bring products to market at an accelerated pace. The ability to quickly iterate designs also fosters innovation, as tweaks and adjustments can be made in real time without the need for extensive retooling.

Moreover, 3D printing facilitates customization on a scale previously unattainable. Manufacturers can produce tailored solutions that meet specific customer needs without incurring the high costs typically associated with custom tooling. This level of personalization not only enhances customer satisfaction but also drives competitive advantage in crowded markets. As businesses increasingly seek to adapt to shifting consumer demands, 3D printing stands out as a pivotal technology that empowers manufacturers to optimize their production processes while maintaining agility and responsiveness.

3D printing technology has revolutionized the manufacturing landscape, particularly in how it redefines cost efficiency. Traditional manufacturing processes often involve significant material waste, whether through excess raw materials or the limitations of subtractive manufacturing techniques. In contrast, 3D printing builds objects layer by layer, using only the necessary amount of material required to produce a part, leading to a substantial reduction in waste. This more efficient use of resources not only conserves materials but also lowers expenses associated with disposal and recycling, making it a financially sustainable option for manufacturers.

Moreover, 3D printing allows for customized and intricate designs that would be costly or impossible to achieve with traditional methods. Manufacturers can produce components tailored to specific requirements without the need for extensive retooling or setup changes. This flexibility not only speeds up production times but also cuts down significantly on the costs involved in developing prototypes and shorter production runs. As industries continue to embrace 3D printing, companies find themselves not only saving on material costs but also enhancing their overall workflow efficiency, positioning them favorably in a competitive market.

This chart illustrates the reduction in waste and material costs associated with the adoption of 3D printing technology in manufacturing. The data represents the percentage decrease in costs and waste across various aspects of manufacturing processes.

Additive manufacturing, commonly known as 3D printing, has ushered in a new era of customization at scale in the manufacturing sector. This technology enables manufacturers to produce highly customized products tailored to individual customer specifications without the constraints of traditional production methods. Unlike conventional manufacturing, which often requires extensive retooling and setup for new items, 3D printing allows for rapid changes in design and functionality, making it possible to meet diverse customer needs quickly and efficiently.

Furthermore, the ability to easily create limited runs of customized products opens avenues for niche markets previously deemed unfeasible. Whether it’s personalized medical devices, unique automotive parts, or bespoke consumer goods, 3D printing empowers businesses to respond to specific customer demands with agility. This shift not only enhances customer satisfaction through tailored solutions but also optimizes supply chains by reducing excess inventory and minimizing waste. As manufacturers leverage this technology to fine-tune their offerings, the potential for innovation and market growth expands, firmly establishing additive manufacturing as a cornerstone of modern production efficiency.

Rapid prototyping has emerged as a transformative force in the manufacturing landscape, significantly enhancing development timelines by leveraging advanced 3D printing solutions. Recent advancements in rapid prototyping technologies are reshaping how products are brought to market, with reports indicating that companies utilizing these methods can reduce prototyping time by up to 90%. This dramatic acceleration allows for increased iteration and refinement of designs, ultimately leading to faster and more efficient production cycles.

Moreover, the integration of artificial intelligence (AI) with 3D printing technology is further revolutionizing rapid prototyping. According to industry experts, AI applications are streamlining the design process, allowing for predictive analytics that can identify potential issues before they arise. This results not only in improved product quality but also in enhanced resource management, reducing waste in production. As industries increasingly adopt these innovative technologies, the potential for expedited development timelines grows, paving the way for more agile and responsive manufacturing practices.

| Reason | Impact on Manufacturing Efficiency | Examples | Time Savings (%) |

|---|---|---|---|

| Rapid Prototyping | Decreases time from concept to prototype | Development of complex parts | 50% |

| Design Flexibility | Allows iterative design changes without delay | Frequent updates on product features | 30% |

| Cost Efficiency | Reduces costs associated with traditional manufacturing | Lower material waste | 20% |

| Customized Solutions | Facilitates production of tailored products | Personalized medical devices | 40% |

| Supply Chain Simplification | Minimizes the need for extensive inventory | On-demand production | 25% |

The rise of 3D printing technology is not just altering the landscape of manufacturing efficiency; it is also transforming the industry into a more sustainable practice. Traditional manufacturing often involves extensive material waste, energy consumption, and emissions. In contrast, 3D printing allows for additive manufacturing, where materials are only used as needed, significantly reducing waste. This method enables the creation of complex designs that often require less material, contributing to a leaner, more resource-efficient production process.

Moreover, 3D printing facilitates local manufacturing, which decreases the need for transportation and its associated carbon footprint. By producing goods closer to the end-user, companies can minimize logistics costs and emissions. Additionally, the ability to quickly prototype and iterate designs leads to a faster innovation cycle, where products can be manufactured with sustainable materials and processes right from the start. As industries increasingly prioritize ecological responsibility, 3D print technology stands out as a vital tool in achieving sustainability goals, paving the way for a greener future in manufacturing practices.