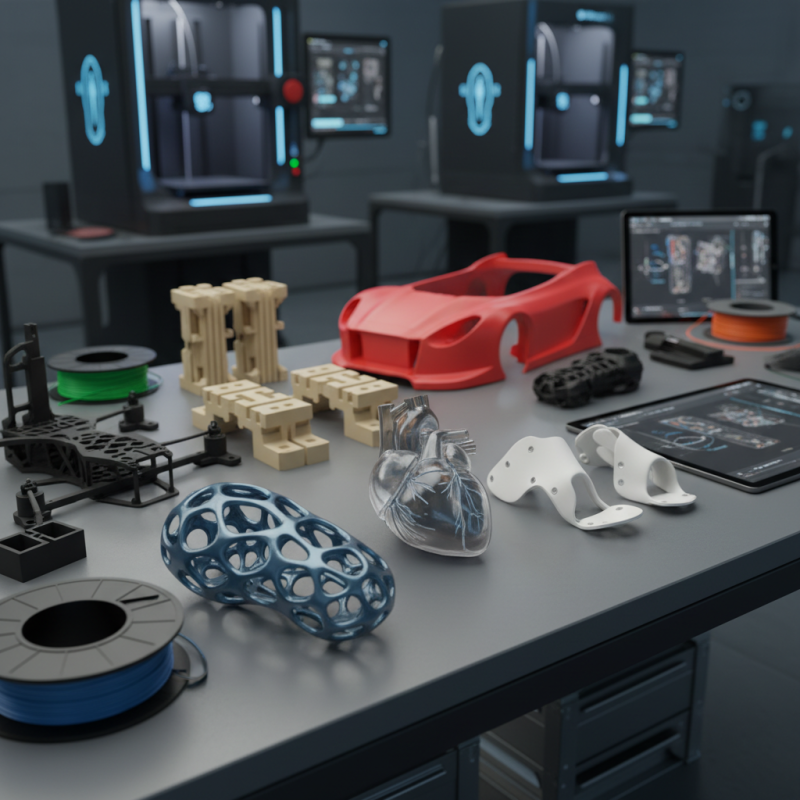

In the realm of modern manufacturing, 3D print parts have emerged as a revolutionary solution for diverse projects. According to Dr. Emily Chen, a leading expert in additive manufacturing, “3D print parts offer unparalleled design flexibility and speed.” This technology streamlines production, allowing designers to create intricate components quickly.

Many industries benefit from 3D print parts, from automotive to healthcare. Designers can produce custom components tailored to specific needs. However, some challenges remain, particularly in achieving the desired material strength and surface quality. These considerations can lead to costly revisions if not addressed early in the design phase.

While the advantages are evident, one must be cautious. Not all projects may suit 3D printing. Traditional manufacturing methods still hold their ground in certain contexts. As the industry grows, understanding when and how to use 3D print parts is crucial for future innovations. Balancing creativity with practicality can lead to impressive outcomes.

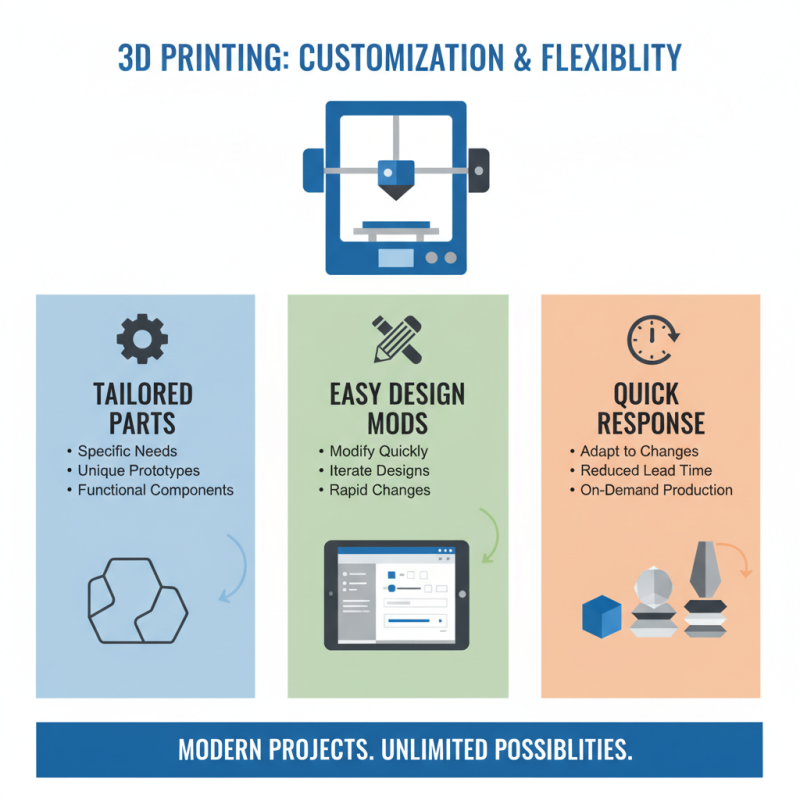

3D printing offers remarkable customization and flexibility for modern projects. This technology allows you to create parts tailored to specific needs. You can modify designs easily, responding quickly to changes in your project requirements. Whether you need a unique prototype or functional components, the adaptability of 3D printing shines.

Imagine designing a custom part that fits perfectly in a tight space. With 3D printing, you can bring that vision to life. The process gives you freedom with materials and shapes. However, sometimes the results may not meet your expectations. You might encounter issues with fit or finish that require further iteration. This imperfection can lead to learning opportunities, pushing you to refine your designs.

Flexibility extends beyond design. You can print on-demand. This means reduced waste and storage issues. Yet, relying solely on this method can be risky. Over time, the quality of prints can vary, leading to inconsistencies. Being aware of these challenges is crucial. Embracing the imperfections can guide you to more innovative solutions.

3D printing has revolutionized the way we approach manufacturing. Cost-effectiveness is a major advantage when compared to traditional methods. According to a report from Wohlers Associates, 3D printing can reduce production costs by 30-60% in some cases. This is significant for small businesses and startups with limited budgets.

Using 3D printed parts often means less material waste. Traditional methods like machining can lead to up to 75% waste. In contrast, additive manufacturing builds parts layer by layer. This efficiency translates into savings. However, it's crucial to remember that not all projects will see beneficial cost impacts. Complex designs may still incur high initial setup costs.

**Tip:** Always calculate the total cost of ownership. This includes not just the printing cost but also post-processing and possible material expenses.

Additionally, 3D printing allows for rapid prototyping. This means faster iterations and getting your product to market sooner. A study by Gartner shows that businesses using 3D printing can accelerate their product development phase by up to 50%. Still, be wary of overestimating the technology's capabilities; suboptimal designs can lead to increased costs and waste.

**Tip:** Experiment with different designs. Test them in small batches before scaling up. You might find areas for improvement that can save time and money.

3D printing has revolutionized the way projects are approached. Time efficiency is one of its standout benefits. Rapid prototyping allows designers to create physical models quickly. This speeds up the testing process significantly. Imagine reducing weeks of development to just days. With 3D printing, adjustments can be made on the fly. Designers can print iterations swiftly. This minimizes downtime and maximizes productivity.

Moreover, the production process closely mirrors the rapid prototyping stages. Tools and components can be printed as needed. This is particularly beneficial for small batches. The ability to produce on demand reduces storage costs. However, this convenience can lead to a temptation to overlook planning. Hasty decisions might lead to design flaws. It’s essential to balance speed with thorough evaluation. Consider potential issues that might arise later. Precise planning should not be ignored in the rush to print.

3D printing is changing the way we approach projects. Sustainability emerges as a key benefit. Traditional manufacturing methods often produce excess waste. In contrast, 3D printing uses only the materials needed. This efficiency can significantly reduce environmental impacts.

Material choices also play a role. Biodegradable filaments are available. They help minimize long-term waste in landfills. Moreover, 3D printing allows for experimenting with innovative materials. This includes composites and recycled plastics. While this sounds promising, there are still challenges. Some materials may not perform as expected. Finding the right balance between efficiency and quality is essential.

Failures can occur with 3D printed components. Not all items are flawless on the first attempt. It’s a learning process that encourages iteration. Each print offers insights into design and material behavior. Embracing imperfections can fuel creativity and lead to discoveries. Overall, 3D printing encourages a more sustainable path forward. Yet, it also compels us to rethink our approaches to production.

| Benefit | Description | Material Efficiency | Sustainability Impact |

|---|---|---|---|

| Customization | Easily customize parts to meet specific project needs. | High, minimal waste material used. | Reduces the need for creating multiple prototypes. |

| Reduced Waste | Only use material necessary for the part. | Very high, almost no surplus material. | Less environmental impact due to lower waste production. |

| Rapid Prototyping | Quickly turn designs into physical parts. | Moderate, depending on design complexity. | Accelerates design cycles, reducing overall resource usage. |

| Lightweight Structures | Create parts with complex geometries that reduce weight. | High, materials can be optimized for weight. | Improves fuel efficiency in transport applications. |

| Resource Accessibility | Access to a wide range of materials for printing. | Varies by material selection. | Enables the use of recycled materials in production. |

| Cost Efficiency | Lower production costs for small runs. | High, reduces costs associated with excess material. | Less energy and material waste translates to lower costs. |

| Stock Reduction | Reduce inventory costs by printing on demand. | Very high, only print what is needed. | Minimizes storage needs and waste from unsold stock. |

| Supply Chain Simplification | Streamlines supply chain logistics with localized production. | Moderate, depending on component sources. | Reduces transportation emissions and impact. |

| Innovation Encouragement | Fosters design freedom and new ideas. | High, encouraging novel designs with minimal waste. | Promotes sustainability through innovative materials and designs. |

| Resilience in Production | Ability to quickly adapt to changes in design or demand. | High, minimizes the need for re-manufacturing. | Supports sustainability with flexibility in production methods. |

3D printing allows for enhanced design capabilities, particularly with complex geometries. This method can produce intricate structures that were once difficult or impossible to create. Designers can explore organic shapes and detailed patterns. For instance, a lightweight lattice design can cut down on unnecessary material while providing strength. This capability opens new avenues in fields like aerospace and automotive industries.

However, designing for 3D printing has its challenges. Not all designs translate seamlessly into the final product. There might be issues with print fidelity or material limitations. Many designers face difficulties optimizing their models for the printing process. They often overlook the need for support structures, which can compromise the project. While the potential is vast, the execution requires careful consideration and adaptation.

Collaborating with engineers during the design phase can refine these ideas. They can provide insights into manufacturability and suggest necessary adjustments. Recognizing the limitations of this technology is crucial. A well-thought-out design may save time and resources. It’s essential to continually learn from each project, even when outcomes don't go as planned. This iterative process drives innovation forward.