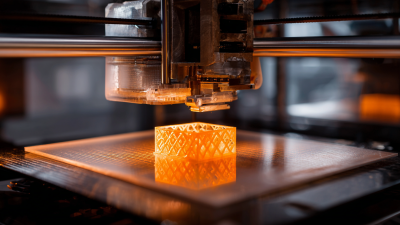

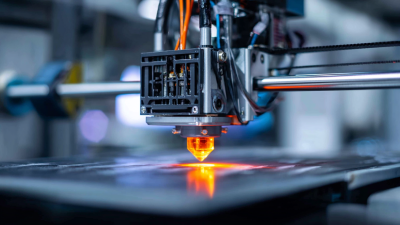

In recent years, the world of manufacturing and design has been transformed by the rapid evolution of 3D print technology. This innovative approach has enabled businesses to create complex structures and prototypes directly from digital files, significantly reducing production times and costs. As we delve into the various digital innovations revolutionizing the 3D print landscape, it becomes evident that these advancements are not just enhancing efficiency but also expanding the possibilities of what can be achieved. From improved materials and software to new printing techniques, these benefits of types in 3D print technology are reshaping industries, empowering creators, and fostering sustainable practices. In this blog, we will explore ten groundbreaking digital innovations that are currently transforming 3D print technology, ensuring that it remains at the forefront of modern manufacturing.

The evolution of 3D printing technology has taken a significant leap forward with the advent of biodegradable filaments, marking a crucial shift in material innovation. Traditional 3D printing materials, often derived from petroleum-based plastics, contribute considerably to environmental pollution. In contrast, biodegradable filaments, made from renewable resources like cornstarch and sugarcane, offer an eco-friendly alternative that decomposes over time, mitigating the long-term impact on our planet. This transition not only enhances the sustainability of additive manufacturing but also aligns with the growing demand for environmentally responsible production practices.

The rise of biodegradable filaments in 3D printing has opened new avenues for industries ranging from healthcare to consumer goods. For instance, in the medical field, biodegradable materials can be utilized for creating temporary implants that dissolve in the body after serving their purpose, reducing the need for surgical removal. Moreover, hobbyists and designers now have access to a wider range of materials that promote sustainability while maintaining the versatility and functionality that 3D printing is known for. The fusion of creativity with ecological mindfulness paves the way for a new era in which technological advancements and environmental stewardship coexist harmoniously.

| Innovation | Description | Impact on 3D Printing | Material Type | Sustainability Factor |

|---|---|---|---|---|

| Biodegradable PLA | A plant-based filament that degrades naturally. | Widely used for eco-friendly prototypes. | Polyactic Acid | High |

| Recycled PETG | Recycled filament derived from post-consumer plastics. | Reduces plastic waste and promotes recycling. | Polyethylene Terephthalate Glycol | Medium |

| Wood Fill Filaments | Filaments infused with wood particles for a natural finish. | Offers aesthetic appeal and sustainable sourcing. | Composite Materials | High |

| Bio-based Nylon | Nylon made from renewable biomass sources. | Durable and flexible with lower environmental impact. | Nylon | Medium |

| Algae-based Filaments | Filaments sourced from algae, promoting sustainable practices. | Supports carbon reduction initiatives. | Algal Biomass | High |

The integration of AI in the design phase of 3D printing is revolutionizing the way custom models are created. AI algorithms streamline the design process by enabling users to generate tailored 3D models effortlessly. With advancements in deep learning, AI can optimize protein pockets for drug interactions, enhancing the customization of materials for specific applications. This parallels the 3D printing industry, where the ability to auto-generate models is empowering designers and engineers, resulting in efficient and innovative productions.

The integration of AI in the design phase of 3D printing is revolutionizing the way custom models are created. AI algorithms streamline the design process by enabling users to generate tailored 3D models effortlessly. With advancements in deep learning, AI can optimize protein pockets for drug interactions, enhancing the customization of materials for specific applications. This parallels the 3D printing industry, where the ability to auto-generate models is empowering designers and engineers, resulting in efficient and innovative productions.

Tips for Utilizing AI in 3D Design:

The rise of cloud-based 3D printing services has revolutionized on-demand manufacturing, offering unprecedented flexibility and efficiency. According to a recent report by MarketsandMarkets, the global 3D printing market is projected to grow from $13.7 billion in 2020 to $34.8 billion by 2026, at a CAGR of 20.8%. This growth is largely driven by the increasing adoption of cloud technology, which enables companies to streamline their production processes while reducing costs.

Cloud-based platforms allow manufacturers to access advanced 3D printing capabilities without the need for significant upfront investments in equipment. For instance, Stratasys and Autodesk have developed cloud solutions that facilitate collaborative design and printing across various locations, thereby shortening the supply chain and decreasing lead times. A study by Wohlers Associates indicates that 63% of manufacturers are now integrating cloud technologies with their additive manufacturing processes, enhancing their ability to produce customized products on demand.

Furthermore, the economic efficiency of on-demand printing is evident in the reduction of waste and inventory costs. The ability to print parts as needed rather than maintaining large stockpiles aligns perfectly with Just-In-Time production practices, which can lead to material savings of up to 70%. As more companies leverage these cloud-based services, the future of manufacturing looks set to be more agile and responsive than ever before.

The integration of the Internet of Things (IoT) into 3D printing technology is catalyzing a wave of efficiency and innovation in the manufacturing sector. By connecting 3D printers to the cloud and other smart devices, manufacturers can monitor and manage their production processes in real-time. This level of connectivity allows for continuous data collection and analysis, enabling companies to detect issues before they escalate and optimize their workflows accordingly. Remote diagnostics and automated adjustments not only decrease downtime but also enhance the overall quality of printed materials.

Moreover, IoT integration facilitates better resource management. Smart sensors can track material usage and alert operators when supplies are running low, reducing waste and ensuring that production schedules are adhered to. Additionally, predictive maintenance powered by IoT analytics helps in identifying when equipment is likely to fail, thus planning maintenance activities without interrupting production lines.

As the demand for customized and rapid prototyping solutions grows, the seamless incorporation of IoT into 3D printing stands out as a transformative strategy that reinforces operational agility and responsiveness in a competitive marketplace.

The ongoing evolution of 3D printing technology is witnessing a promising shift towards sustainability, significantly reducing waste across various industries. Traditional manufacturing processes often lead to material excess and environmental burdens. In contrast, 3D printing enables a more efficient use of resources through additive manufacturing, where materials are built layer by layer, minimizing scrap and enabling the production of complex geometries that would otherwise be impossible. This shift not only conserves raw materials but also opens the door to new sustainable materials, including bioplastics and recycled filaments, which align manufacturing with environmental goals.

Moreover, innovations in 3D printing are fostering a circular economy by facilitating on-demand production. Companies can now create products tailored to specific needs without overproducing, thus greatly diminishing excess inventory and waste. By adopting digital inventory practices, businesses can print items only when required, reducing the footprint associated with transportation and storage. This approach not only cuts costs but also aligns with a broader commitment to ecological responsibility, paving the way for a future where efficiency and sustainability coexist harmoniously in manufacturing practices.