In the rapidly evolving landscape of manufacturing, 3D printing metal has emerged as a groundbreaking technology that offers numerous advantages for businesses seeking innovation and efficiency. As companies explore new methods to optimize production processes, the potential of metal 3D printing becomes increasingly compelling. This technology not only allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods but also provides significant cost savings and reduced material waste. By harnessing the capabilities of 3D printing metal, businesses can enhance their product offerings, improve manufacturing flexibility, and accelerate time-to-market. In this exploration, we will delve into the various ways organizations can leverage this transformative technology to stay competitive in an evolving industry, highlighting key strategies and best practices for successful implementation.

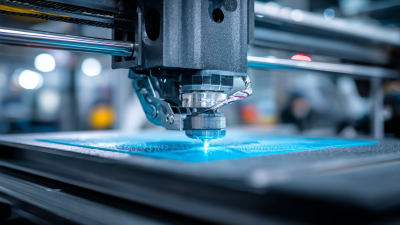

3D metal printing has emerged as a revolutionary technology that transforms the way businesses approach manufacturing. Unlike traditional metal fabrication techniques, 3D metal printing utilizes additive manufacturing, where materials are layer by layer deposited to create complex components. This method allows for greater design freedom, enabling engineers to produce intricate geometries that were previously impossible or cost-prohibitive to manufacture using conventional approaches.

3D metal printing has emerged as a revolutionary technology that transforms the way businesses approach manufacturing. Unlike traditional metal fabrication techniques, 3D metal printing utilizes additive manufacturing, where materials are layer by layer deposited to create complex components. This method allows for greater design freedom, enabling engineers to produce intricate geometries that were previously impossible or cost-prohibitive to manufacture using conventional approaches.

Understanding the basics of 3D metal printing involves familiarizing yourself with key processes such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). DMLS uses a laser to fuse metal powders, creating dense and strong parts suitable for aerospace, automotive, and medical applications. EBM, on the other hand, employs an electron beam in a vacuum to weld metal layers, making it ideal for high-performance components. Both technologies highlight the advantages of reduced material waste and shorter lead times, making them attractive options for businesses looking to innovate and enhance production efficiency.

Exploring the potential of metal 3D printing for businesses opens up numerous applications and opportunities across various industries. As the market for metal 3D printing is projected to grow significantly—from $1.19 billion in 2025 to $3.62 billion by 2030—companies can leverage this technology to enhance their manufacturing processes. Industries such as aerospace, automotive, and healthcare are already adopting metal additive manufacturing to produce complex geometries and lightweight parts with greater efficiency and reduced waste.

Moreover, the integration of 3D printing with emerging technologies like artificial intelligence and the Internet of Things is paving the way for innovative solutions in manufacturing. These technologies can facilitate more efficient resource management and automation, enabling businesses to align with sustainable practices while meeting rising demand. As firms recognize the strategic advantages of incorporating metal 3D printing into their operations, they position themselves to thrive in an increasingly competitive landscape, tapping into new markets and enhancing product offerings.

| Application Area | Industry | Benefits | Challenges |

|---|---|---|---|

| Prototyping | Aerospace | Rapid iteration and reduced time-to-market | Material constraints and design limitations |

| Spare Parts Production | Automotive | On-demand production and storage saving | Regulatory compliance and scalability |

| Custom Tools and Fixtures | Manufacturing | Increased efficiency and tailored solutions | Initial setup costs and material costs |

| Medical Devices | Healthcare | Personalization and improved patient outcomes | Complexity in regulations and standards |

| Art and Design | Art & Design | Creative freedom and innovative designs | Market niche and production volume |

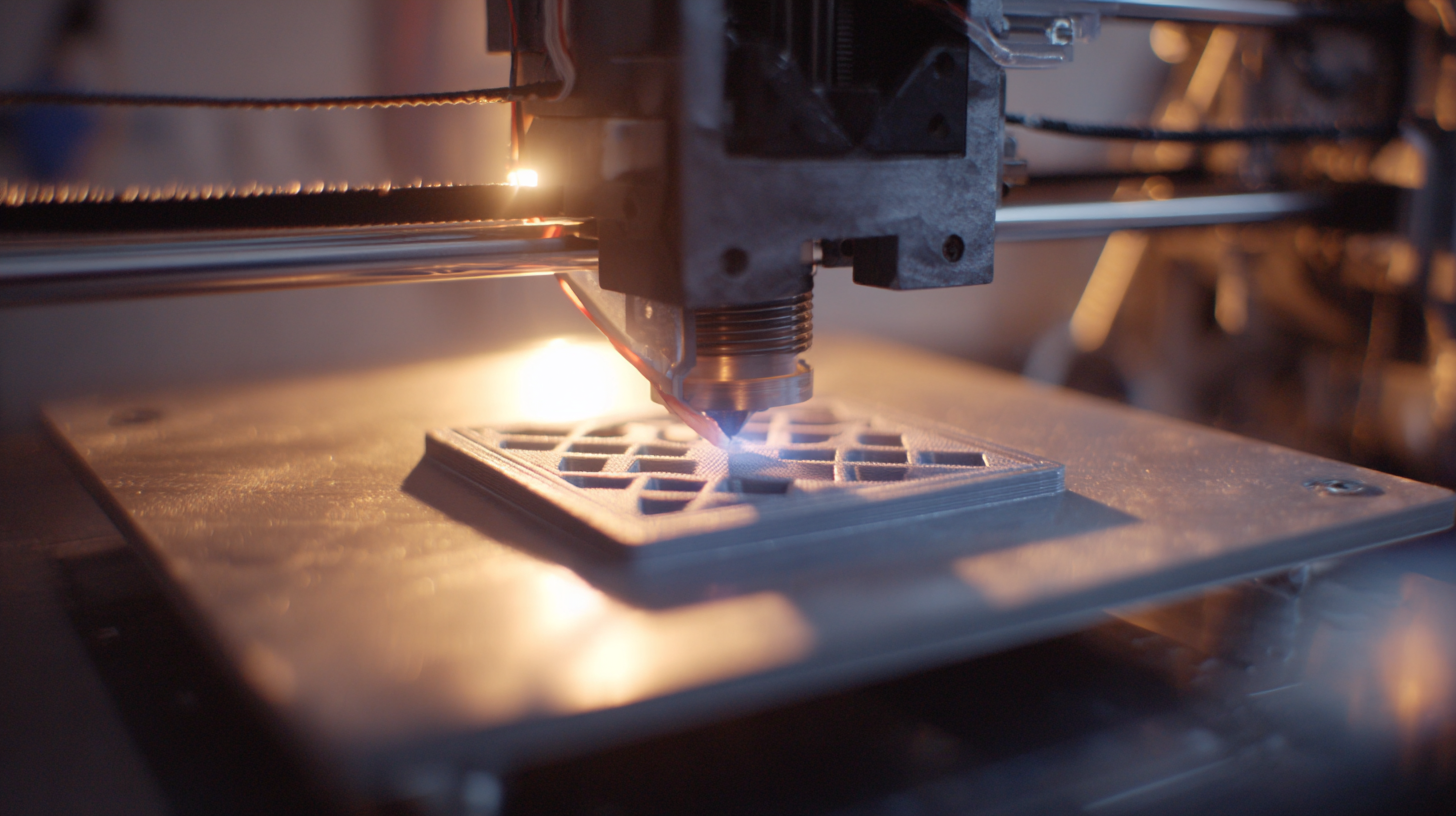

When exploring the potential of 3D printing metal for your business, selecting the right equipment is crucial. With advancements in technology, there are numerous metal 3D printers on the market that cater to specific industry needs, from aerospace to healthcare. Understanding the scale of production you require, the types of metal materials you intend to use, and the level of precision necessary will guide your choice. For instance, if you're focusing on small batch manufacturing, certain models are optimized for efficiency and quality, allowing for the production of intricate designs without compromising on durability.

Additionally, it's essential to consider the versatility and support available for the 3D printer you choose. Some models offer a broader range of compatible materials and enhanced features for post-processing, which can significantly benefit your workflow. Researching the latest offerings in 3D metal printing with a focus on user reviews will help identify solutions that align with your operational goals. By prioritizing equipment that meets your specific needs, you can harness the full potential of 3D printing in driving innovation and efficiency in your business.

This chart illustrates the potential applications of 3D printing metal in various industries, highlighting the importance of selecting the right 3D printing equipment for specific business needs.

Navigating material choices is crucial for businesses looking to leverage the advantages of 3D printing metal. The recent report by Wohlers Associates highlights that the metal additive manufacturing market is expected to reach $3.4 billion by 2025, an indication of the growing interest and investment in this technology. Selecting the right material can significantly enhance the performance characteristics of printed parts, impacting strength, durability, and overall functionality. Common materials like titanium and aluminum alloys offer unique benefits; for instance, titanium boasts a high strength-to-weight ratio, making it ideal for aerospace applications.

Navigating material choices is crucial for businesses looking to leverage the advantages of 3D printing metal. The recent report by Wohlers Associates highlights that the metal additive manufacturing market is expected to reach $3.4 billion by 2025, an indication of the growing interest and investment in this technology. Selecting the right material can significantly enhance the performance characteristics of printed parts, impacting strength, durability, and overall functionality. Common materials like titanium and aluminum alloys offer unique benefits; for instance, titanium boasts a high strength-to-weight ratio, making it ideal for aerospace applications.

Moreover, the advancements in material formulations have led to improved precision and usability in metal 3D printing. According to a study by the Additive Manufacturing Users Group, businesses that adopt tailored metal powders for specific applications can improve their production rates by up to 60%. This increase not only optimizes operational efficiency but also allows for greater design flexibility, essential for custom manufacturing. As industries continue to explore the potential of 3D-printed metal components, understanding and navigating these material choices will remain a key factor in achieving enhanced performance and competitive advantage.

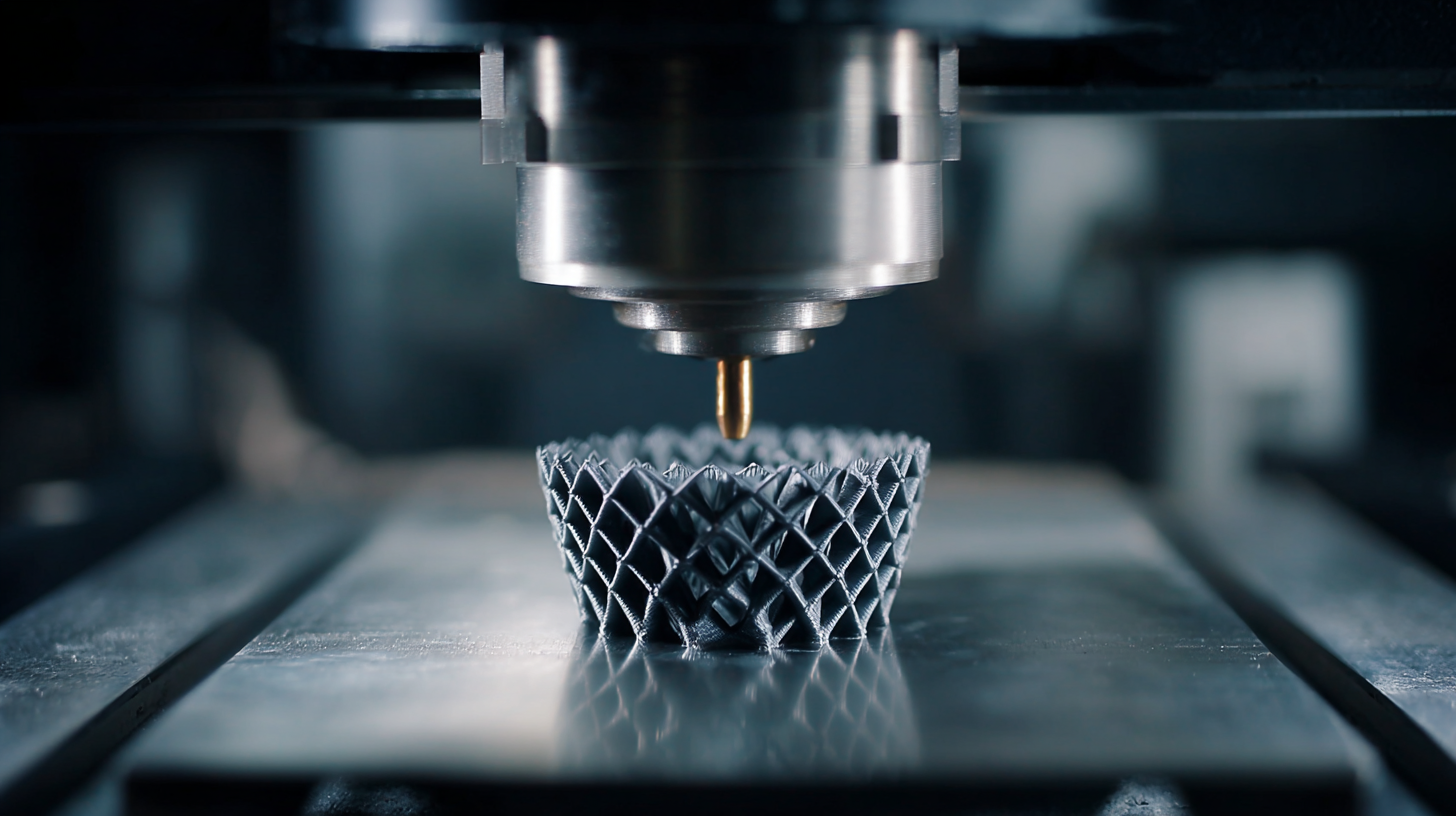

Integrating metal 3D printing into your existing production workflow presents a groundbreaking opportunity for businesses looking to enhance their manufacturing capabilities. As the demand for faster and more efficient production processes escalates, metal-additive manufacturing enables companies to create complex components with improved mechanical, electrical, and thermal functionalities. This technology supports innovative designs that traditional manufacturing methods struggle to achieve, thus positioning firms to stay competitive in an evolving market.

Recent advancements in metal-polymer heterogeneous architectures are pivotal in transforming how products are manufactured, allowing for the seamless integration of various functionalities within a single component. This approach can streamline production lines and reduce material waste, enhancing overall operational efficiency. Moreover, partnerships and software developments are making these technologies more accessible, enabling businesses to easily integrate metal 3D printing into their existing workflows. As the industry continues to grow, with estimates suggesting significant market expansion by 2035, now is the time for companies to explore and adopt these transformative capabilities.