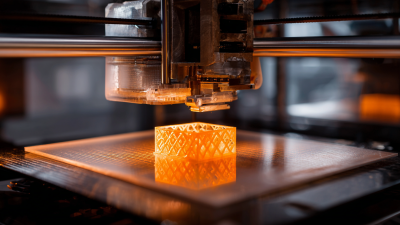

The landscape of manufacturing is undergoing a paradigm shift, largely driven by the advancements in 3D printing technology. A report by the Wohlers Associates suggests that the global 3D printing market is projected to reach $35.6 billion by 2024, highlighting its pivotal role in reshaping production processes across various industries. As manufacturers increasingly embrace additive manufacturing, they benefit from reduced lead times, lower material waste, and the flexibility to create complex geometries that were previously unimaginable. The ability to swiftly prototype and iterate designs not only enhances innovation but also allows for customization at scale, catering to the evolving needs of consumers. With significant investments in 3D printing technology and software development, the future promises a more efficient, sustainable, and digitized manufacturing environment, making it imperative for industry stakeholders to adapt and leverage these solutions effectively.

The evolution of 3D printing technologies is reshaping the landscape of manufacturing industries, bringing about unprecedented changes in production processes and product development. According to a report by SmarTech Analysis, the global 3D printing market is projected to reach $42.9 billion by 2027, demonstrating a compound annual growth rate (CAGR) of 21.0% from 2022 to 2027. This growth is driven by advancements in materials, increasing automation, and the integration of artificial intelligence in additive manufacturing.

Moreover, the adoption of 3D printing in sectors such as aerospace, automotive, and healthcare has shown remarkable results. A study by Wohlers Associates estimates that metal 3D printing could grow from a $1.1 billion industry in 2020 to about $5.2 billion by 2026, highlighting its significance in producing lightweight, complex components that traditional methods struggle to achieve. As manufacturers leverage these technologies to reduce waste and enhance customization, the future of manufacturing appears not only more efficient but also more adaptable to the evolving demands of the market.

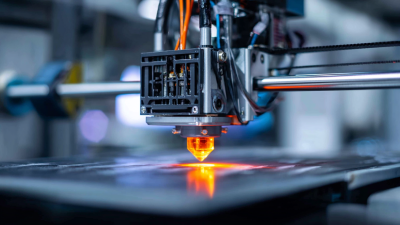

The advent of 3D printing is reshaping several key industries, driving innovation and efficiency. In manufacturing, sectors such as aerospace, automotive, and healthcare are experiencing profound transformations. Aerospace companies utilize 3D printing to produce lightweight components that enhance fuel efficiency while reducing production time.

Meanwhile, the automotive industry leverages this technology for rapid prototyping and the customization of parts, leading to faster turnaround times and reduced costs.

In the healthcare sector, 3D printing is making strides in creating personalized medical devices and even bioprinting tissues. This innovation not only improves patient outcomes but also streamlines the development process for new treatments.

Tip: When exploring 3D printing in your industry, consider starting with small-scale projects to understand the technology's integration with existing systems.

Additionally, collaborating with 3D printing experts can provide valuable insights and accelerate the learning curve. Embracing these innovations not only fosters competitive advantage but also prepares businesses for future manufacturing trends.

The advent of 3D printing technology is revolutionizing the manufacturing landscape, offering significant advantages over traditional methods. According to a report by SmarTech Analysis, the global 3D printing market is expected to reach $34.8 billion by 2024, up from $12 billion in 2020, highlighting the rapid adoption of this technology across various industries. One major advantage of 3D printing is its ability to streamline production processes, reducing lead times from weeks to mere hours. This agility not only accelerates product development but also allows manufacturers to respond swiftly to market demands.

Moreover, 3D printing enables the creation of complex geometries that are often impossible to achieve with conventional manufacturing methods. McKinsey's research indicates that companies utilizing 3D printing have reduced material waste by an average of 30%, significantly promoting sustainability. The flexibility of additive manufacturing allows for personalization at scale, catering to specific customer needs without incurring significant additional costs. As industries continue to embrace this innovative approach, the impact of 3D printing on manufacturing efficiency and environmental responsibility will undoubtedly grow.

The shift towards 3D printing in manufacturing presents both significant challenges and unparalleled opportunities. As businesses seek to innovate, integrating 3D printing technology requires a fundamental change in mindset and operations. One major challenge is the initial investment cost that includes acquiring 3D printers and the necessary software. Many companies may hesitate, fearing that these costs outweigh the anticipated benefits.

Tip: To mitigate these costs, companies should consider starting with small-scale projects that demonstrate the technology's capabilities without extensive upfront investment. This allows for a gradual ramp-up in 3D printing applications while minimizing risk.

On the other hand, the benefits of adopting 3D printing are vast. Manufacturers can leverage the technology for rapid prototyping, which not only speeds up the development process but also allows for customization in production. This leads to tailored products that meet specific consumer demands, enhancing customer satisfaction and potentially driving sales.

Tip: Collaboration with 3D printing specialists can provide invaluable insights and support, helping manufacturers navigate the complexities of integrating this technology seamlessly into their existing workflows. By embracing this partnership, businesses can efficiently tap into the transformative potential of 3D printing.

As 3D printing technology continues to evolve, its application in manufacturing industries is poised for transformative changes. A report by SmarTech Analysis projects that the 3D printing market for industrial applications will reach $16.5 billion by 2025, showcasing a burgeoning interest in additive manufacturing. Industries are increasingly recognizing the advantages of this technology, including reduced time-to-market and the ability to produce complex geometries that are often impossible with traditional methods.

One of the most promising trends in the future of 3D printing is the integration of artificial intelligence (AI) and machine learning, which enhances design optimization and process efficiency. According to Gartner, by 2024, 75% of organizations will be utilizing AI for product development and manufacturing, indicating a significant shift towards smarter production techniques. In aerospace and automotive sectors, for instance, companies are adopting 3D printing for creating lightweight prototypes that contribute to fuel savings and overall performance improvements. Coupled with advancements in materials science, we are on the brink of a new era where 3D printing not only streamlines manufacturing but also leads to innovative solutions in product design and sustainability.