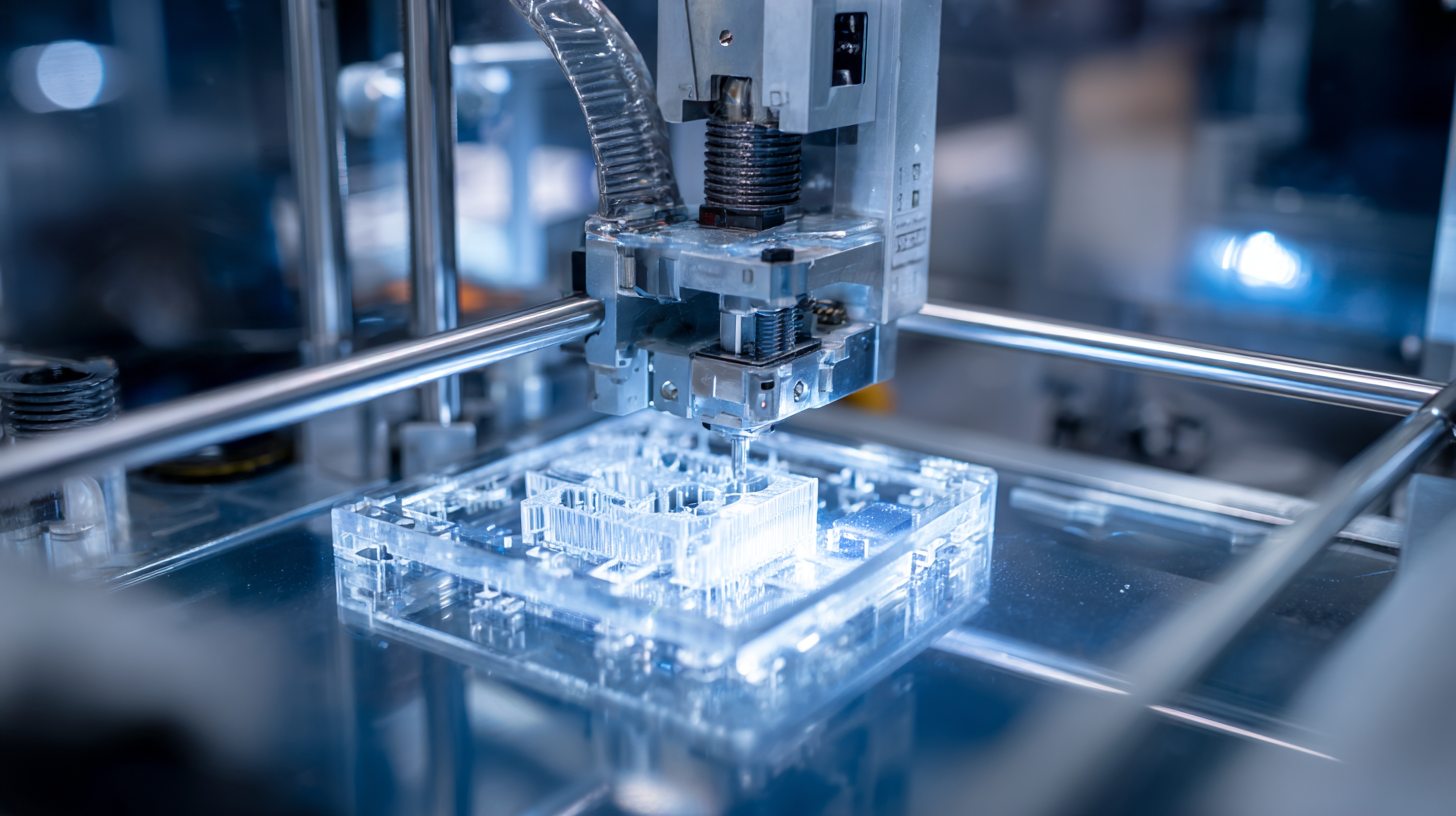

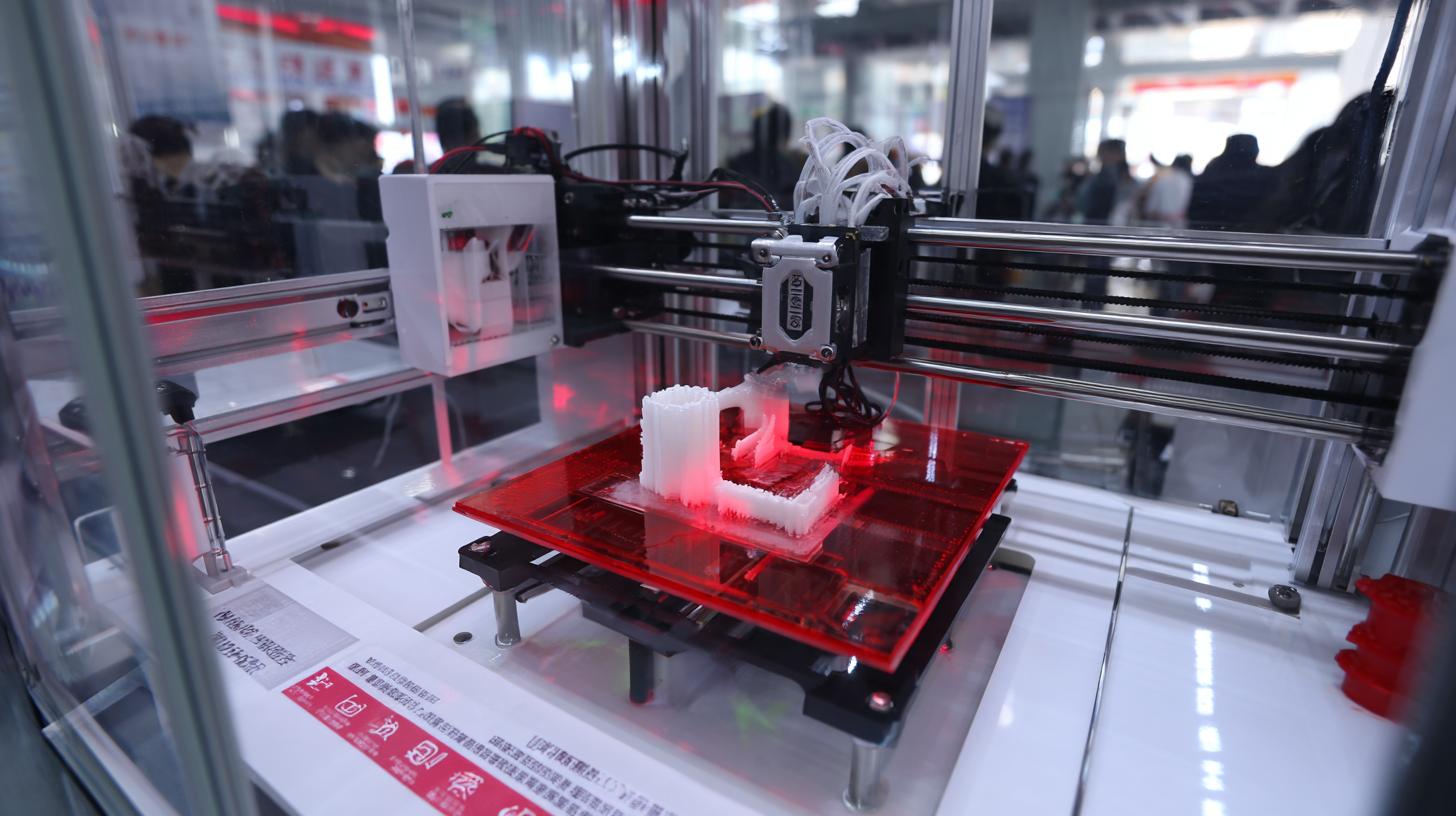

The 138th China Import and Export Fair in 2025 is poised to showcase groundbreaking innovations in rapid prototyping 3D printing, reflecting the cutting-edge developments in manufacturing and design technologies. As industries increasingly seek efficient ways to bring ideas to market, rapid prototyping 3D printing stands out as a vital tool, enabling designers and engineers to transform intricate concepts into tangible prototypes with unprecedented speed and accuracy. This event will provide a platform for leading companies to exhibit their latest advancements, explore collaborative opportunities, and engage in discussions about the future of production processes. Attendees will witness how rapid prototyping 3D printing is not only revolutionizing product development but also enhancing customization and reducing costs across various sectors. The fair will highlight the importance of these innovations in fostering a competitive edge in an ever-evolving global marketplace.

At the 138th China Import and Export Fair in 2025, 3D printing is set to showcase innovative applications that are transforming product development across various sectors. One particularly striking example is the recent advancements in 3D printing within the pharmaceutical industry, where companies have gained FDA approval for multiple products, notably with a third 3D-printed drug entering clinical trials. This exemplifies the growing trend of integrating 3D printing technology to accelerate drug development and customization.

The desktop 3D printing market is anticipated to grow significantly, with projections estimating an increase from $3 billion in 2023 to $9.5 billion by 2032. This expansion is driven primarily by the increasing demand for rapid prototyping and small-scale manufacturing. Similarly, the metal 3D printing market is expected to rise from $2.48 billion in 2024 to approximately $10.09 billion by 2032, indicating a robust compound annual growth rate (CAGR) of about 20.3%. These trends highlight the pivotal role of 3D printing in advancing manufacturing processes, enhancing product design capabilities, and ultimately improving time-to-market for innovative solutions.

At the 138th China Import and Export Fair 2025, rapid prototyping through 3D printing is poised to showcase groundbreaking technological advances that redefine design and manufacturing processes. One of the key developments includes the integration of artificial intelligence in prototype design. AI algorithms can analyze vast datasets to predict the most efficient designs, thereby reducing the time and resources involved in the prototyping phase. This synergy between AI and 3D printing not only accelerates production but also enhances the quality and functionality of the prototypes produced.

Another notable trend is the evolution of materials used in rapid prototyping. The introduction of biocompatible and environmentally friendly materials is revolutionizing industries such as healthcare and automotive. These advanced materials not only allow for the creation of customized prototypes that meet specific regulatory requirements but also support sustainable manufacturing practices. Furthermore, advancements in multi-material printing techniques enable the development of prototypes with varying properties, making it easier to conduct thorough testing and improve product designs. As these innovative trends take center stage at the fair, they promise to inspire the future of rapid prototyping and its applications across various sectors.

This chart illustrates the advancements in rapid prototyping techniques based on different technological innovations showcased during the fair, highlighting the growing significance of each technology in the 3D printing landscape.

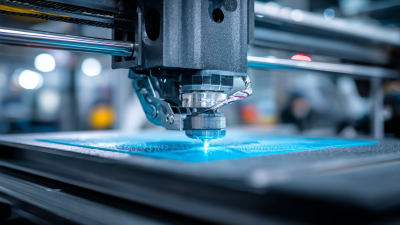

At the 138th China Import and Export Fair 2025, sustainability in 3D printing emerges as a cornerstone of innovation. As the global community increasingly focuses on environmental responsibility, the demand for eco-friendly materials in rapid prototyping has surged. Companies participating in the fair are showcasing advancements in biodegradable filaments and recycled materials that not only minimize waste but also reduce the carbon footprint of manufacturing processes. This paradigm shift encourages industries to embrace sustainable practices without compromising on quality or performance.

Moreover, the innovative use of natural resources in producing 3D printing materials highlights a new era of eco-conscious design. From hemp-based composites to algae-derived plastics, these materials are gaining traction among designers and engineers alike. This trend not only supports the circular economy but also appeals to a consumer base that prioritizes environmental sustainability. As businesses showcase their commitment to eco-friendly practices at the fair, it becomes evident that the future of 3D printing lies in harmonizing technology with nature, fueling both creativity and responsible production.

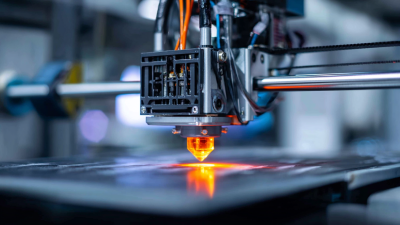

The impact of 3D printing on supply chain and manufacturing efficiency is becoming increasingly significant, particularly as industries seek agile solutions in today's fast-paced market. According to a report by Wohlers Associates, the global 3D printing market is projected to grow to $35.6 billion by 2024, underscoring the technology's transformative potential. Companies that adopt 3D printing can significantly reduce lead times and production costs, enabling faster iterations and more customized products. With the capability to produce complex geometries and intricate designs, 3D printing streamlines the production process, minimizes waste, and optimizes material use.

Tips: To maximize the benefits of 3D printing in your operations, consider starting with prototyping. This allows you to refine designs and reduce production errors. Additionally, investing in training for your workforce can lead to a more skilled team that effectively utilizes the technology.

The integration of 3D printing into supply chains also enhances flexibility and resilience. A report from Ernst & Young indicates that 65% of manufacturers plan to invest in 3D printing to better adapt to market changes. By localized production capabilities, companies can respond to demand fluctuations more rapidly, reducing reliance on traditional supply chain systems that may be slow or unreliable. Embracing this technology can foster a more efficient and sustainable manufacturing environment.

| Trend | Description | Impact on Supply Chain | Impact on Manufacturing Efficiency |

|---|---|---|---|

| Sustainable Materials | Development of biodegradable and recyclable printing materials. | Reduces waste and carbon footprint in supply chains. | Enhances brand image and meets consumer demands for sustainability. |

| On-Demand Production | Ability to produce parts or products as needed, reducing inventory. | Minimizes storage costs and potential overproduction. | Streamlines production processes and reduces lead times. |

| Customization | Ability to easily personalize products according to customer specifications. | Increases customer satisfaction and loyalty through tailored offerings. | Improves productivity by integrating customization into the manufacturing process. |

| Integration of AI | Use of AI for design optimization and predictive maintenance in 3D printing. | Enhances decision-making and efficiency across the supply chain. | Increases machine uptime and reduces downtime costs. |

| Cloud-Based Printing | Remote access to 3D printers and design files facilitates global operations. | Enables faster shipment and production regardless of location. | Simplifies coordination and scaling of manufacturing resources. |

The landscape of global trade is witnessing a paradigm shift driven by advancements in 3D printing technology. According to Market Research Future, the global 3D printing market is projected to reach approximately $34.8 billion by 2026, growing at a CAGR of 24.5%. This growth is fundamentally altering traditional business models, allowing companies to optimize their supply chains, reduce production costs, and enhance customization capabilities. Notably, the integration of 3D printing in rapid prototyping is enabling businesses to develop innovative products faster and more efficiently, thus catering to the dynamic demands of consumers.

Furthermore, the 138th China Import and Export Fair 2025 will showcase how 3D printing solutions are not only simplifying the production process but also creating new avenues for international trade. The adoption of additive manufacturing is making it possible for businesses to produce items on-demand, effectively reducing inventory costs and minimizing waste. A report by the Wohlers Associates highlights that over 50% of companies using 3D printing for production are experiencing significant impacts on their business models, with implications for local and global markets alike. As companies increasingly leverage 3D printing technology, the future of global trade is poised for transformation, marked by efficiency, sustainability, and innovation.