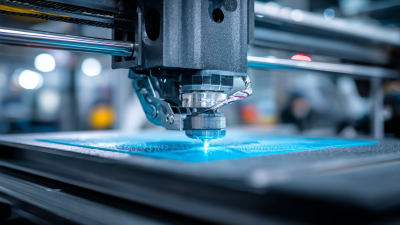

As the automotive industry grapples with rising production costs and increasing demand for customization, automotive 3D printing has emerged as a transformative solution. According to a report by Wohlers Associates, the global 3D printing market in the automotive sector is projected to reach 10.6 billion USD by 2027, driven by the technology's potential to reduce production costs by as much as 50%. This innovative approach enables manufacturers to streamline processes, minimize material waste, and shorten lead times, ultimately enhancing efficiency and profitability. Furthermore, a study by the Automotive Industry Action Group highlights that 70% of automotive executives are considering or already implementing 3D printing techniques to address challenges related to prototyping and small-batch production. By leveraging automotive 3D printing, companies can not only cut expenses but also gain a competitive edge in a rapidly evolving market.

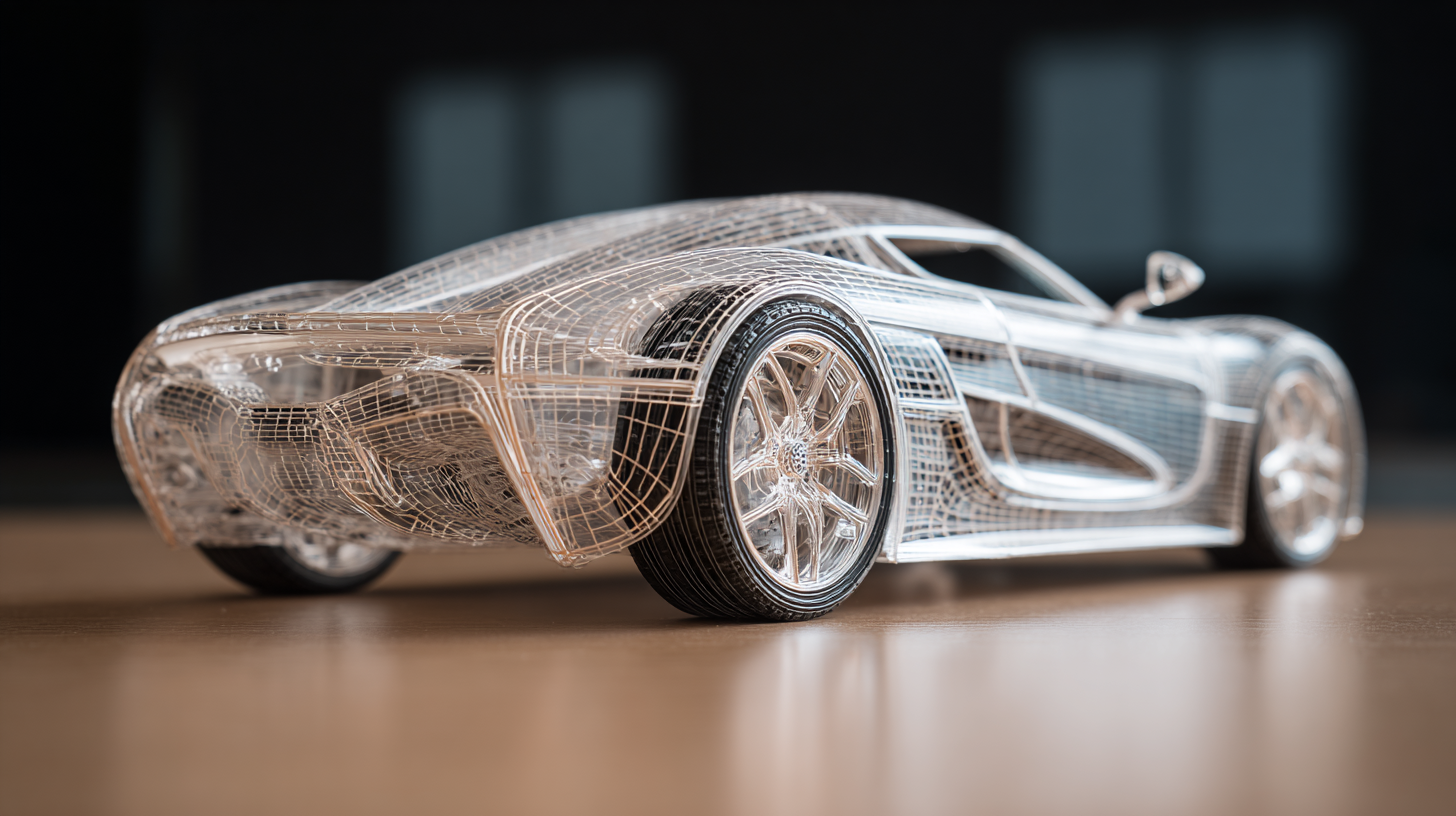

Integrating 3D printing into automotive manufacturing presents a transformative opportunity to significantly cut production costs. By strategically employing additive manufacturing techniques, companies can streamline their processes, reducing the time and resources required for prototyping and part production. Implementing a gradual transition to 3D printing can allow manufacturers to identify which components benefit most from this technology, enabling them to focus on high-impact areas. For example, custom parts, which are often costly to produce using traditional methods, can be efficiently manufactured using 3D printing, resulting in time savings and decreased material waste.

Furthermore, collaboration with suppliers and investment in training employees can enhance the effectiveness of 3D printing in automotive production. By fostering partnerships with additive manufacturing specialists, companies can access advanced technologies and expertise that unlock additional cost savings. Equipping the workforce with the necessary skills to operate and maintain 3D printing equipment ensures that organizations can fully capitalize on the benefits. As automotive manufacturers embrace these strategies, they not only reduce costs but also increase their competitiveness in a rapidly evolving industry, paving the way for innovative vehicle designs and faster market delivery.

Leading automakers are increasingly adopting 3D printing technologies, resulting in remarkable cost savings and efficiencies. According to a report by SmarTech Analysis, the automotive sector can achieve production cost reductions of 30-50% by integrating additive manufacturing into their processes. For instance, major brands like Ford and BMW have utilized 3D printing to produce complex components that were previously expensive and time-consuming to manufacture. These innovations not only streamline production but also enable rapid prototyping, allowing for quicker iterations and modifications.

Tips for leveraging 3D printing in automotive manufacturing include investing in quality materials and advanced printers to ensure durability and precision. Additionally, automakers should consider collaborating with 3D printing service providers to access expertise and technology that can enhance production capabilities. As highlighted in the Wohlers Report, the market for 3D printing in this industry is expected to grow significantly, indicating a pivotal shift towards more sustainable and cost-efficient manufacturing practices.

By examining these case studies, it becomes evident that embracing 3D printing not only cuts costs but also fosters innovation in product design. Automakers that adopt these advanced technologies can enhance their competitive edge while reducing lead times and improving supply chain flexibility.

| Automaker | 3D Printing Technique | Cost Reduction (%) | Production Stage | Benefits |

|---|---|---|---|---|

| Automaker A | Selective Laser Sintering | 30% | Prototype Development | Faster turnaround for designs |

| Automaker B | Fused Deposition Modeling | 40% | End-use Parts | Reduced material waste |

| Automaker C | Stereolithography | 35% | Tooling | Shortened manufacturing time |

| Automaker D | Digital Light Processing | 50% | Mass Customization | Increased market adaptability |

The integration of artificial intelligence (AI) in the automotive industry is revolutionizing design processes, particularly through digital prototyping and Design for Manufacture (DFM) methodologies. These innovations enable manufacturers to streamline operations, drastically cutting development time and costs. Research indicates that the adoption of digital twins can reduce overall development times by 20-50%, offering significant efficiency improvements in vehicle design and production processes.

Furthermore, as the global automotive 3D printing market is forecasted to grow from USD 4.43 billion in 2024 to USD 15.33 billion by 2031, industries are increasingly leveraging additive manufacturing to prototype complex parts quickly and cost-effectively. This technology not only enhances creativity in design but also addresses the urgency for manufacturers to adopt DFM principles, which simplify production and facilitate the rapid adaptation of electric vehicle innovations. The strategic use of these advanced technologies stands to benefit automotive companies by decreasing their development costs and accelerating the time to market for new models.

The automotive industry is undergoing a transformation as it embraces advanced materials through 3D printing technology. By leveraging high-performance materials such as carbon fiber-reinforced polymers and metal alloys, manufacturers are not only enhancing the durability of their components but also achieving significant cost savings. A report from SmarTech Analysis indicates that the use of advanced materials in additive manufacturing can result in a cost reduction of up to 50% in certain production processes, through minimized waste and reduced material costs.

As companies seek to innovate, they must consider materials that meet both strength and lightweight requirements. For example, using nylon composites in structural applications can provide the necessary toughness while also being cost-effective. It's essential to stay informed about emerging material trends; resources like the Wohlers Report often provide insights into new developments in this space.

Tip: When selecting materials for 3D printing, consider pilot testing various options to determine the best cost-to-performance ratio.

Additionally, collaborating with suppliers who specialize in advanced materials can unlock unique formulations that enhance performance. Firms like BASF and Solvay are already pioneering sustainable solutions in the automotive sector, demonstrating that innovation in materials is not just beneficial for cost savings but can also contribute to eco-friendliness in vehicle production.

Tip: Engage in workshops or seminars focused on material innovations to stay ahead of industry trends and discover potential partnerships.

In today's rapidly evolving automotive industry, leveraging 3D printing technology has emerged as a game-changer for streamlining supply chains and minimizing production costs. By utilizing 3D printing, manufacturers can significantly reduce inventory levels and shipping expenses. For instance, a recent report indicates that the 3D printing market in manufacturing is projected to surpass $40 billion by 2030, highlighting its growing importance in operational efficiency and cost reduction.

One notable implementation is the trial run of onboard 3D printing on container ships to facilitate faster and more cost-effective repairs. This innovative approach not only addresses immediate logistical challenges but also reduces the frequency and volume of parts requiring transportation. By producing components on-demand, companies can efficiently manage their inventory, leading to remarkable savings in shipping costs and minimizing storage overhead.

**Tips:** To optimize supply chain management using 3D printing, companies should consider investing in in-house 3D printing capabilities to minimize lead times. Additionally, forming strategic partnerships with 3D printing service providers can enhance flexibility in production and further reduce costs. Embracing real-time data analytics can also aid in anticipating supply demands, allowing for more proactive inventory management.

This bar chart illustrates the significant reduction in average production costs achieved through the implementation of 3D printing technology in the automotive industry, showcasing a potential decrease of up to 50% compared to traditional manufacturing methods.