In today's fast-paced manufacturing landscape, the adoption of rapid prototyping 3D printing has emerged as a game-changer, revolutionizing how products are designed and produced. According to a report by Wohlers Associates, the 3D printing industry is projected to reach a staggering $44.5 billion by 2026, reflecting the growing demand for innovative manufacturing solutions. This transformative technology allows manufacturers to reduce the time from concept to production, enabling them to rapidly iterate designs and improve product quality with greater efficiency.

World-class factories in China are at the forefront of this movement, leveraging advanced capabilities in rapid prototyping 3D printing to offer exceptional manufacturing services. As businesses seek to enhance their competitiveness in a global market, understanding the key advantages of rapid prototyping 3D printing has never been more critical.

In today's rapidly evolving manufacturing landscape, rapid prototyping has emerged as a game changer, significantly impacting how products are developed and produced. Understanding the fundamentals of rapid prototyping is crucial for manufacturers aiming to enhance efficiency and meet growing consumer demands for customization. This innovative approach allows for the quick creation of prototypes, enabling designers to test and refine their ideas in real-time, thereby accelerating the product development cycle.

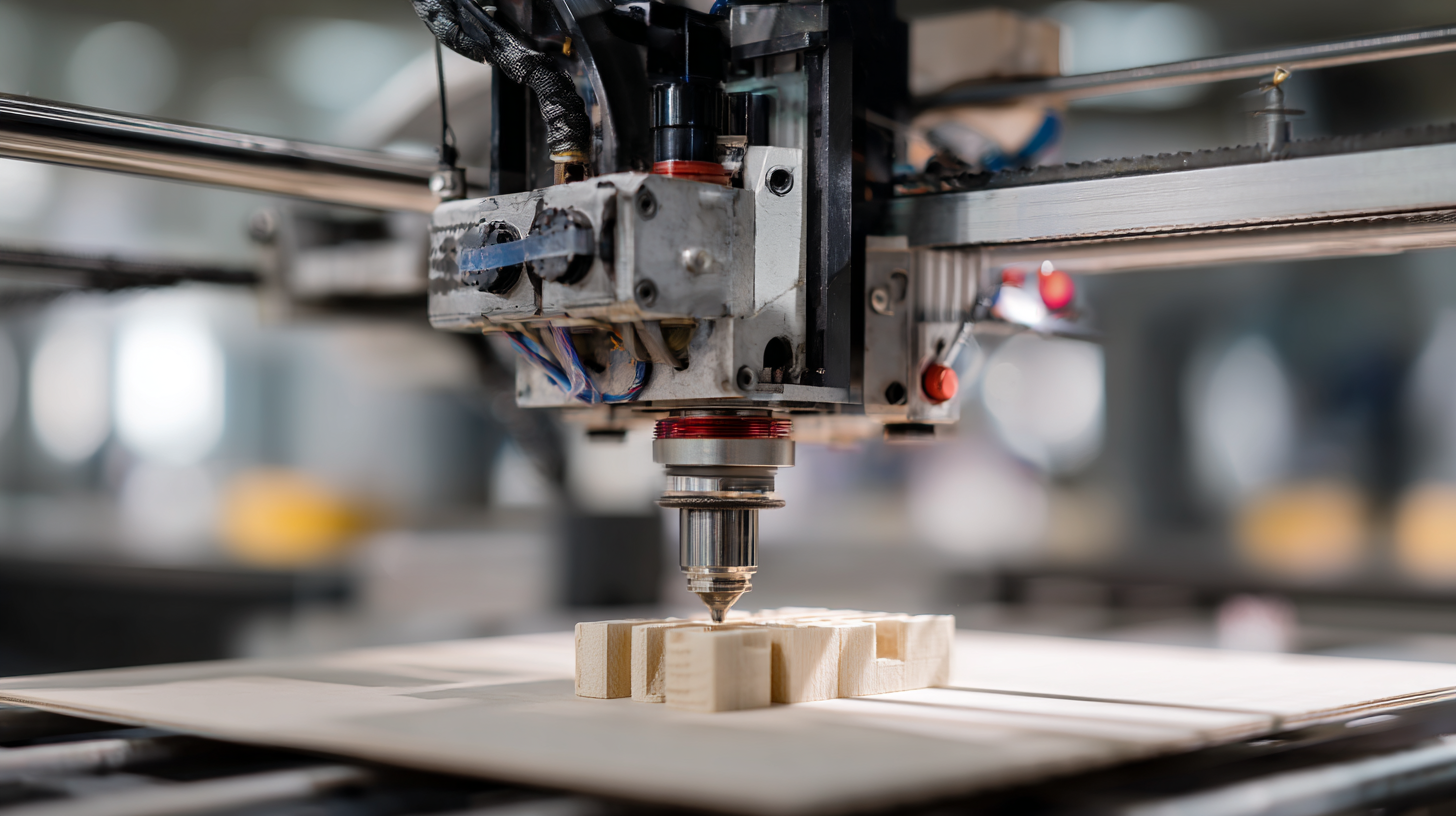

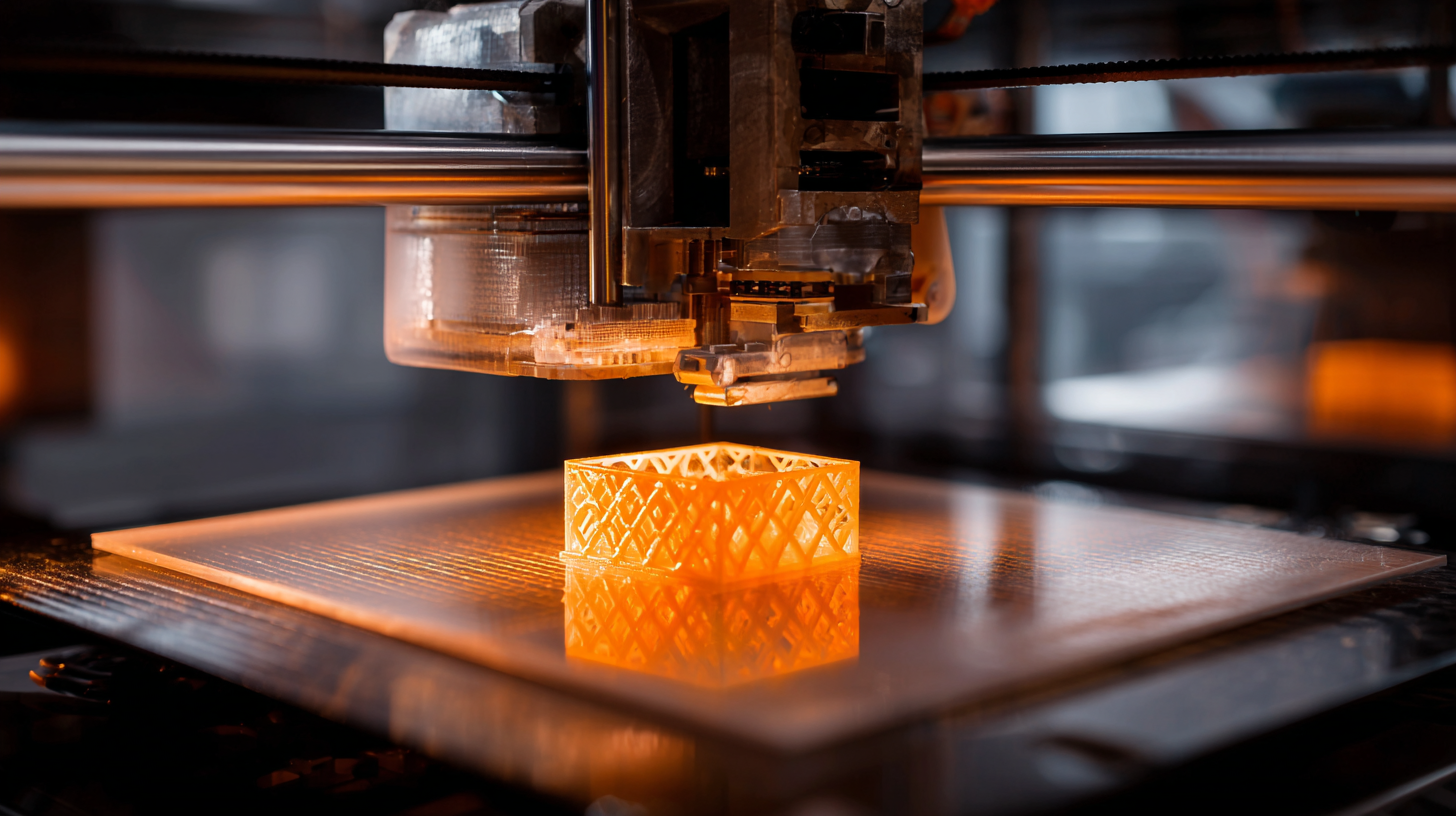

The integration of advanced 3D printing technologies in manufacturing not only streamlines the prototyping process but also opens up new avenues for creativity and innovation. With various methods available, such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), manufacturers can choose the right technique to suit their specific needs, enhancing the precision and quality of prototypes. Furthermore, as the demand for personalized products continues to rise, the ability to produce unique prototypes quickly is becoming increasingly vital, positioning rapid prototyping as a foundational element in the future of smart manufacturing.

When evaluating manufacturing quality in the realm of 3D printing, several key characteristics set the top providers apart from the rest. A report by Wohlers Associates highlights that the global 3D printing market is projected to reach $34.8 billion by 2024, emphasizing the increasing reliance on high-quality prototyping services. Leading 3D printing companies distinguish themselves through superior material selection, precision in print fidelity, and adherence to stringent regulatory standards. For instance, providers that utilize advanced polymer and metal materials are not only able to enhance product durability but also ensure that designs meet specific industry requirements.

Furthermore, customer support and post-processing capabilities play critical roles in assessing manufacturing quality. According to a study from SmarTech Analysis, 74% of manufacturers rank customer service as a primary factor when selecting a 3D printing provider. This highlights the necessity for clear communication and availability during the prototyping process, ensuring that clients receive not only quality products but also valuable insights throughout development. By focusing on these characteristics, businesses can make informed decisions while partnering with the right 3D printing service to drive innovation in their manufacturing processes.

This chart represents the key advantages of rapid prototyping 3D printing in manufacturing, highlighting their importance levels. Speed and quality control are critical for success in the manufacturing sector.

In the rapidly evolving landscape of manufacturing, cost-effectiveness in rapid prototyping has emerged as a critical focus. According to a report by Wohlers Associates, 3D printing is projected to grow at an annual rate of 25.76% from 2021 to 2028, reflecting its increasing importance in reducing production costs while maintaining quality. By utilizing advanced materials and techniques, manufacturers can significantly lower the financial barrier to launching new products. For instance, the cost of prototype development can decrease by up to 40% when employing efficient 3D printing processes compared to traditional manufacturing methods.

Moreover, the balance between price and quality remains paramount. A study by the American Society for Testing and Materials (ASTM) emphasizes that companies leveraging rapid prototyping can shorten their product development cycles by as much as 50%, allowing faster time-to-market. This efficiency not only boosts profitability but also enhances competitive agility. As a result, businesses are increasingly investing in best practices for 3D printing technologies, ensuring they achieve high-quality prototypes without sacrificing affordability. This shift is crucial for industries ranging from aerospace to consumer goods, where the need for rapid iteration is essential in meeting market demands.

| Feature | Standard Method | 3D Printing | Cost (USD) | Time (Days) |

|---|---|---|---|---|

| Material Waste | High | Low | 500 | 10 |

| Prototype Accuracy | Moderate | High | 1200 | 5 |

| Lead Time | 4-8 weeks | 1-2 weeks | 750 | 14 |

| Design Complexity | Limited | Unlimited | 900 | 7 |

| Production Volume | Large | Small to Medium | 3000 | 30 |

Choosing the right filament for your 3D printing project is critical to achieving the desired quality and functionality of your prototypes. According to a report from Wohlers Associates, the global 3D printing market is projected to reach $35.6 billion by 2024, with a significant portion driven by advancements in material technology. Different filaments offer unique properties, such as strength, flexibility, and heat resistance, which can dramatically affect the performance of the final product. For instance, ABS is favored for its durability and ease of post-processing, while PLA is often chosen for its eco-friendliness and ease of use.

When selecting filament, factors such as the intended application, required mechanical properties, and environmental considerations should guide your decision. Reports indicate that over 60% of industry professionals prioritize mechanical performance when selecting materials for rapid prototyping. Additionally, using advanced materials like Nylon or Carbon Fiber composites can greatly enhance the strength-to-weight ratio of printed parts, making them ideal for functional prototypes. Ultimately, a well-informed choice in material not only enhances the prototype's effectiveness but also contributes to a more streamlined and efficient manufacturing process.

When selecting a manufacturer for rapid prototyping with 3D printing,

customer support and service emerge as critical factors that can significantly influence the overall experience.

Companies often overlook the importance of responsive customer service until challenges arise during the production process.

A manufacturer who prioritizes open communication can not only resolve issues swiftly but also provide valuable insights throughout the project,

making the collaboration seamless and efficient.

Moreover, excellent customer support fosters a partnership where feedback is welcomed and implemented.

This interaction can lead to improvements in the design and manufacturing processes, ensuring the final product aligns closely with the client's vision.

A manufacturer that excels in customer service will proactively engage with clients, offering expert advice and timely updates.

These practices enhance trust and satisfaction, critical components that contribute to the long-term success of any prototyping project,

especially in an industry that thrives on innovation and swift turnaround times.