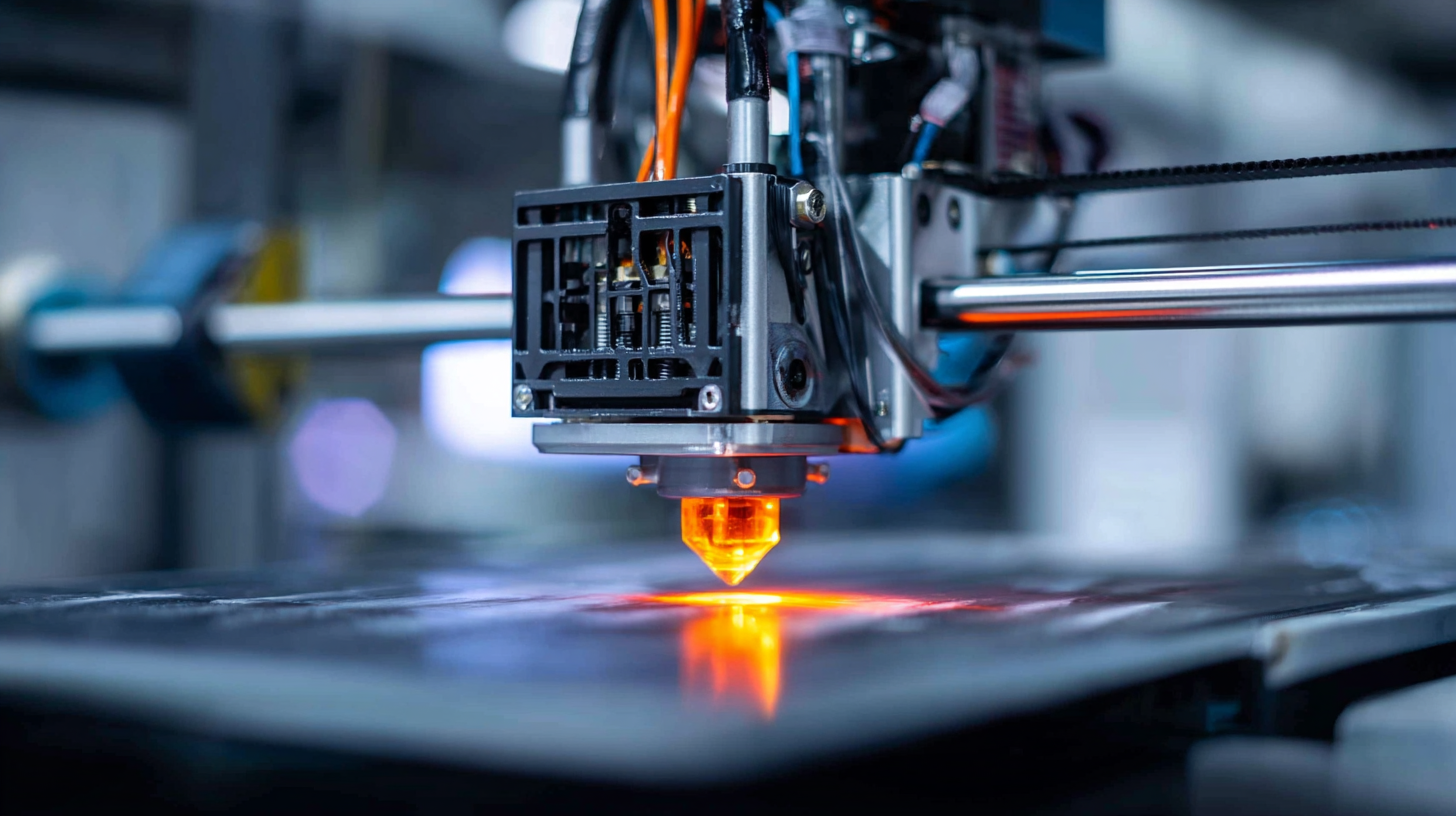

The emergence of rapid 3D printing technology is revolutionizing the manufacturing landscape, delivering unprecedented efficiencies and capabilities. According to recent reports from industry analysts, the global 3D printing market is expected to reach $62.79 billion by 2028, growing at a CAGR of 23% from 2021. This surge is primarily driven by advancements in rapid 3D printing techniques, which enable companies to reduce production times and costs significantly. With the ability to create complex geometries and customize products on-demand, businesses across various sectors—including aerospace, automotive, and healthcare—are harnessing this innovative technology to enhance their operational efficiency and accelerate their product development cycles. As we explore the top innovations within the realm of rapid 3D printing, it becomes evident that these transformative solutions are not merely enhancing productivity; they are reshaping the very fabric of global manufacturing.

The rapid evolution of 3D printing materials is redefining the landscape of manufacturing processes worldwide. With recent advancements, manufacturers are now able to utilize a diverse range of materials that enhance durability, flexibility, and sustainability. For instance, high-performance polymers and metal composites are increasingly being adopted to produce intricate parts that can withstand extreme conditions, making them ideal for industries like aerospace and automotive. This shift not only speeds up production times but also allows for greater design freedom, enabling the creation of complex geometries that traditional manufacturing methods cannot achieve.

Moreover, the introduction of bio-based and recyclable materials in 3D printing is playing a crucial role in promoting sustainability in manufacturing. Companies are now prioritizing materials that minimize environmental impact, aligning with global efforts to reduce carbon footprints. Innovations such as biodegradable filaments and reusable resin materials are becoming staples in eco-friendly manufacturing practices. This commitment to using advanced, sustainable materials not only boosts efficiency but also paves the way for a more responsible and circular economy in the manufacturing sector. As these technologies continue to develop, the implications for global production will be profound, fostering a future where efficiency and sustainability go hand in hand.

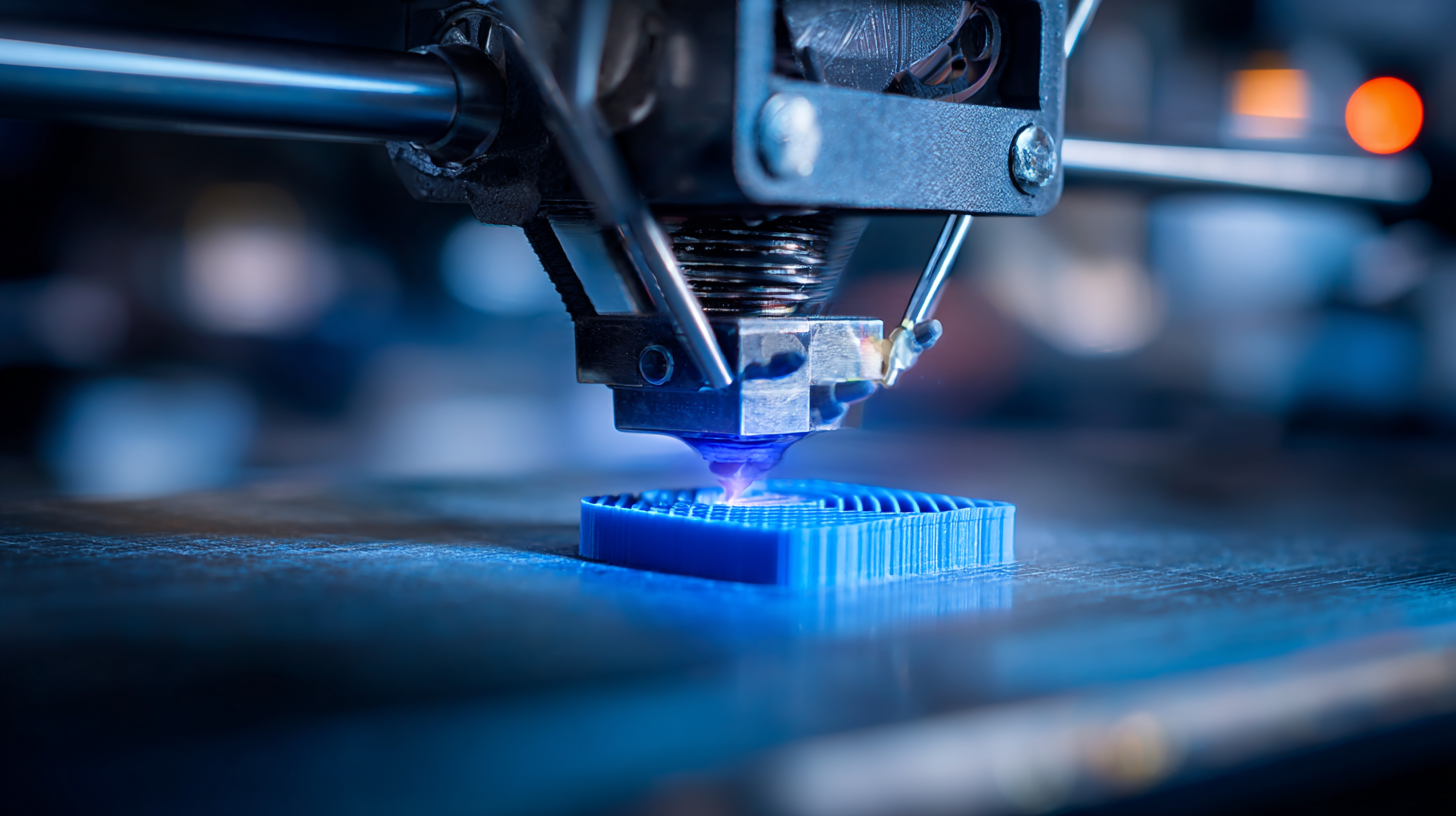

The rapid evolution of 3D printing technology has been significantly enhanced by the integration of artificial intelligence (AI) and machine learning (ML). These advanced technologies are not just augmenting the capabilities of 3D printers, but they are also transforming how industries approach manufacturing. By leveraging AI algorithms, manufacturers can now optimize designs and streamline production processes in real-time, leading to a reduction in material waste and an increase in product accuracy.

Moreover, machine learning plays a crucial role in predictive maintenance and quality control within 3D printing systems. By analyzing data from previous printing operations, machine learning models can predict potential failures before they occur, ensuring uninterrupted production and reducing downtime. This proactive approach helps manufacturers maintain high efficiency and quality standards. The synergy of AI and ML with rapid 3D printing is ushering in a new era of intelligent manufacturing, where adaptability and speed are key drivers of success in a competitive global market.

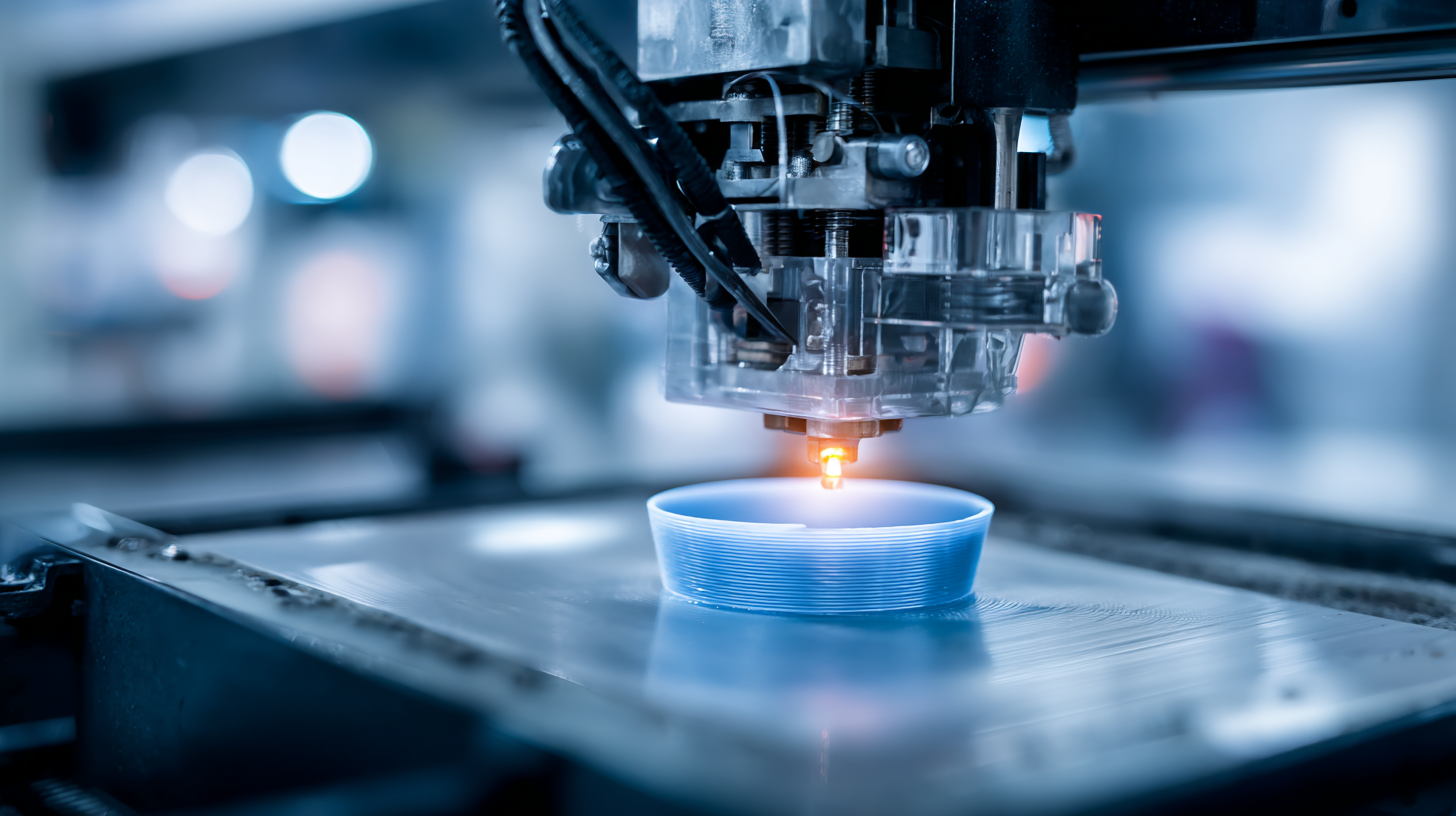

The future of 3D printing innovations is increasingly intertwined with sustainability, reflecting a global shift towards environmentally friendly manufacturing practices. As industries embrace rapid 3D printing technology, manufacturers are finding innovative ways to minimize waste and reduce their carbon footprint. By utilizing biodegradable materials and adopting energy-efficient production techniques, companies can create products that meet consumer demands without compromising ecological integrity.

Sustainable 3D printing not only addresses environmental concerns but also enhances efficiency in the supply chain. With the ability to produce on-demand and localized manufacturing, businesses can significantly decrease transportation emissions and inventory costs. Moreover, advancements in recycling technologies are enabling the reuse of 3D printed materials, further promoting a circular economy. As these trends continue to evolve, it’s clear that sustainability will play a crucial role in shaping the next generation of 3D printing innovations, allowing manufacturers to achieve both economic and environmental goals.

This chart illustrates the impact levels of various innovations in rapid 3D printing on global manufacturing efficiency, highlighting the importance of material efficiency, production speed, cost reduction, waste minimization, and design flexibility.

The impact of 3D printing on supply chain optimization cannot be overstated. Recent studies indicate that 3D printing can reduce supply chain lead times by up to 75%, dramatically improving responsiveness to market demands. With the ability to produce complex geometries and customized parts on-demand, companies can significantly minimize inventory costs and reduce the risk of overproduction. According to a report by Wohlers Associates, the global 3D printing market is projected to reach $35.6 billion by 2024, highlighting its essential role in modern manufacturing processes.

**Tip:** To fully leverage the benefits of 3D printing, businesses should invest in training their workforce on additive manufacturing technologies. This investment not only enhances operational efficiency but also fosters a culture of innovation within the organization.

Moreover, as to the redesign aspect, companies are now able to rethink traditional product designs entirely. By utilizing 3D printing, manufacturers can iterate products quickly and cost-effectively, creating prototypes in just hours instead of weeks. This rapid prototyping capability allows for a more dynamic approach to product development, enabling firms to adapt to consumer feedback swiftly. As a result, businesses are seeing a reduction in product development cycles by as much as 60%.

**Tip:** Implementing a systematic approach to integrate 3D printing into product development strategies can help organizations stay ahead of the competition and meet evolving consumer expectations.

| Innovation Type | Description | Impact on Manufacturing | Supply Chain Optimization |

|---|---|---|---|

| Material Innovations | Advanced materials enable faster production and enhance product durability. | Increased production speed and reduced waste. | Allows for localized production, reducing transportation costs. |

| Software Advancements | Integration of AI and machine learning for design optimization. | Streamlined design processes leading to faster time-to-market. | Enhanced forecasting and inventory management. |

| Sustainability Practices | Use of bioplastics and environmentally friendly materials. | Reduced overall carbon footprint of manufacturing processes. | Minimizes waste and promotes recycling in supply chains. |

| Automation and Robotics | Integration of automated systems in 3D printing processes. | Higher production efficiency and consistency. | Faster response times and improved logistics. |

| On-Demand Production | Production of parts only as needed, reducing inventory. | Lower inventory costs and minimized overproduction. | Adapts quickly to market changes and consumer demand. |

The world of 3D printing is rapidly evolving, and as we approach 2025, several emerging technologies are set to reshape the landscape of global manufacturing. One notable trend is the rise of high-performance composite materials that enhance the durability and versatility of 3D printed products. These materials, characterized by their exceptional bonding properties, are enabling manufacturers to design more complex and functional components that meet diverse industry needs. This shift towards advanced materials is crucial for sustaining competitive advantages in sectors like aerospace, automotive, and consumer goods.

Equally exciting is the growing intersection of 3D printing with food production. The advancements in 3D food printing technology not only facilitate the customization of edible products but also contribute to sustainability by reducing food waste. As manufacturers leverage these innovations, we can expect a surge in bespoke dining experiences that cater to individual tastes and dietary requirements. Moreover, large-format 3D printing is making waves in the entertainment industry, with startups driving initiatives that could transform how props, sets, and even costumes are created for film and theater. As these trends converge, they promise to unlock new efficiencies and possibilities within global manufacturing systems, signaling a transformative era ahead.